9 Chapter 9: ADA and Elevators

Elevators are crucial in modern architecture, allowing for the efficient movement of people between different floors within buildings. The 2010 ADA Standards for Accessible Design includes comprehensive requirements in Section 407 to ensure these essential mobility aids are accessible to all, including those with disabilities. The standards cover various aspects of elevator design and operation, emphasizing compliance with Section 407 and ASME A17.1 standards. Automatic operation and regular maintenance are mandated to uphold safety and functionality, preventing violations of federal laws due to non-functioning features. This introduction leads into a detailed examination of specific requirements for visible signals at elevator call buttons, hoistway signage, elevator doors, and elevator cars, ensuring that each component contributes to the overall accessibility and safety of elevator systems.

Visible Signals

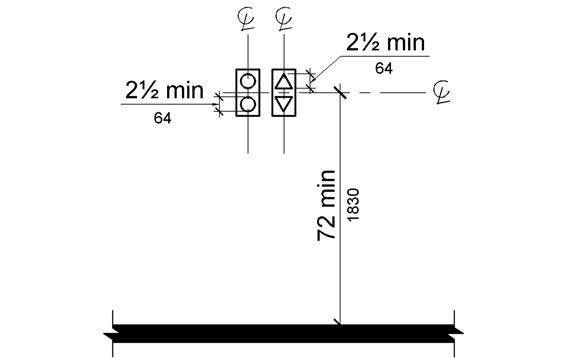

Section 407.2.2.2 of the ADA Standards for Accessible Design specifies requirements for visible signals at elevator hall call buttons. Here are the specific details:

- Height and Positioning: Visible signal fixtures must be centered at a minimum height of 72 inches above the finished floor or ground.

- Size of Signal Elements: The visible signal elements must have a minimum dimension of 2.5 inches measured along the vertical centerline of the element.

- Visibility: The signals must be visible from the floor area adjacent to the hall call button to ensure they can be easily seen by users including those in wheelchairs.

These requirements are designed to ensure that the signals are accessible and clearly visible to all users, including those with mobility or visual impairments, enhancing the usability and safety of elevator systems

Hoistway Signs

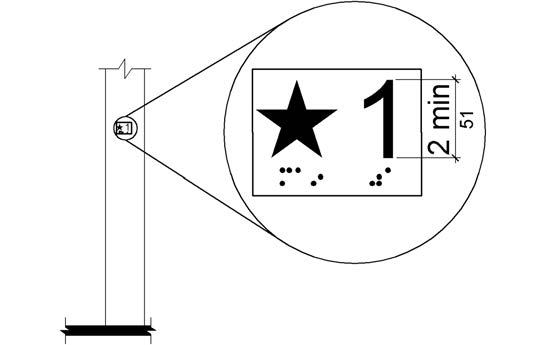

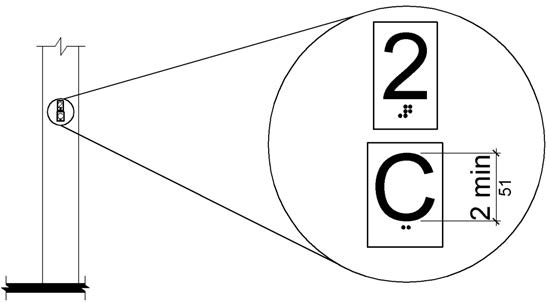

Section 407.2.3 of the ADA Standards for Accessible Design specifies requirements for signage at elevator hoistways. A hoistway, also known as an elevator shaft, is a vertical passageway built to accommodate an elevator in a building. It houses the elevator car and its moving components, like the cables and counterweights. The hoistway is enclosed, typically by walls. It extends from the lowest level of the building to the highest, providing a controlled environment for the elevator to travel safely between floors. It also contains safety equipment to prevent the elevator from falling in case of a mechanical failure.

407.2.3.1 Floor Designation: Signs providing floor designations at elevator hoistway entrances must comply with specific standards for tactile characters and Braille. The signs should be placed on both jambs of the hoistway entrances. Tactile characters must be at least 2 inches high, and a tactile star must be included on both jambs at the main entry level to denote a significant floor, such as the ground floor.

407.2.3.2 Car Designations: For destination-oriented elevators, tactile car identification signs must also be provided on both jambs of the hoistway, immediately below the floor designation signs. These must also be in both tactile characters and Braille, with characters also maintaining a minimum height of 2 inches.

These provisions ensure that the signage is both visible and tactile to accommodate a wide range of users, including those with visual impairments, facilitating easier navigation and identification of elevator locations and functions.

Elevator Door Requirements

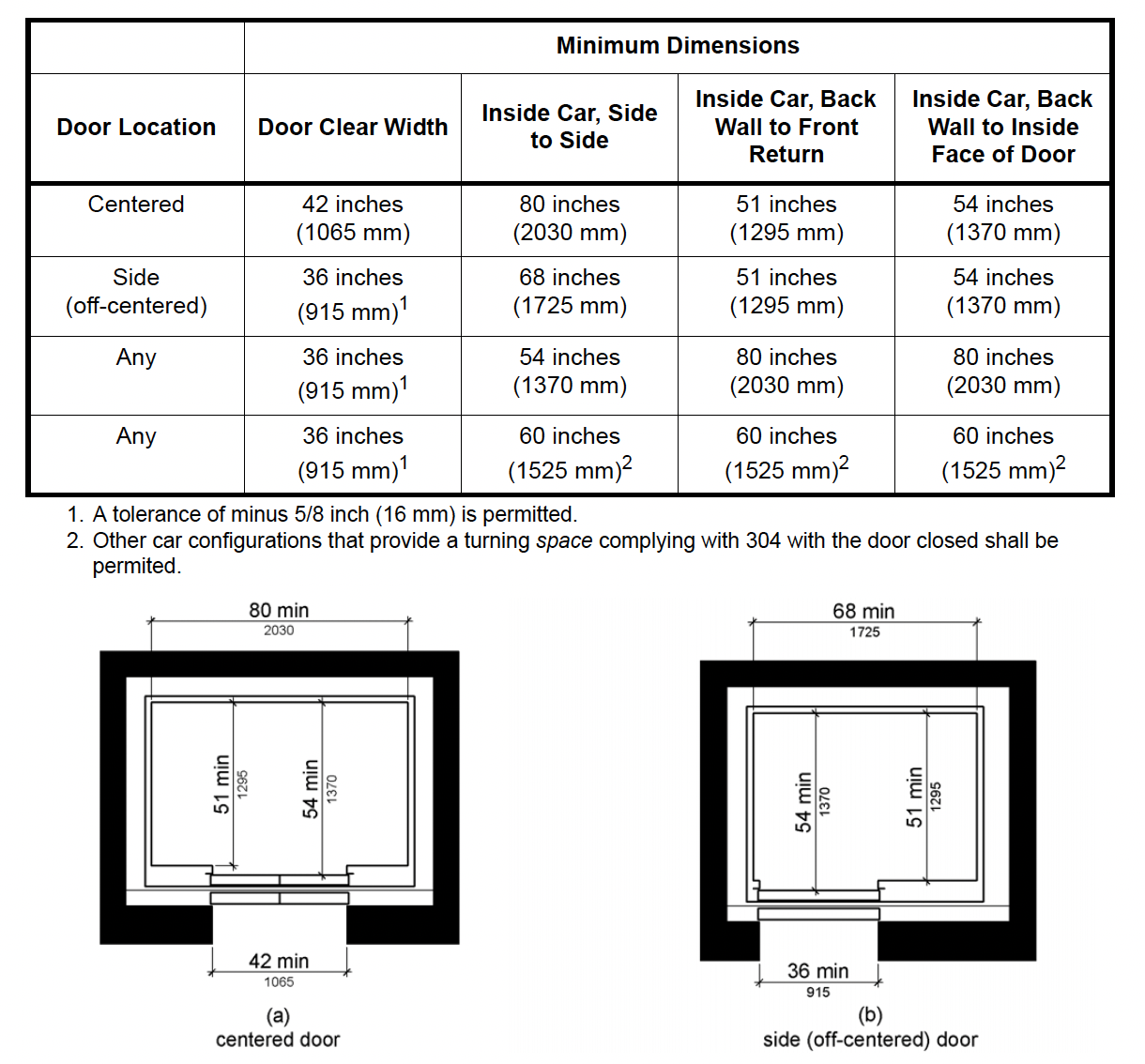

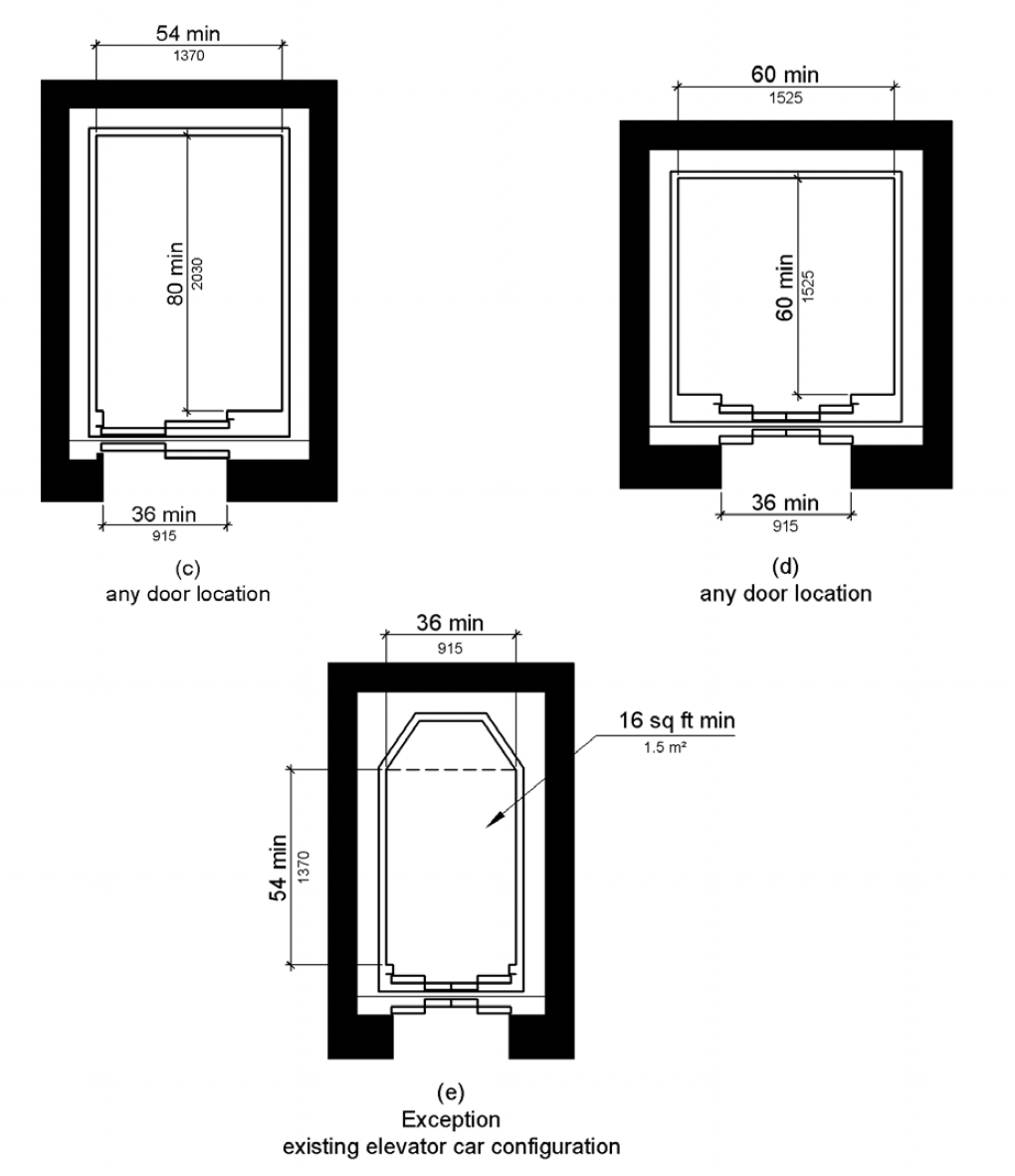

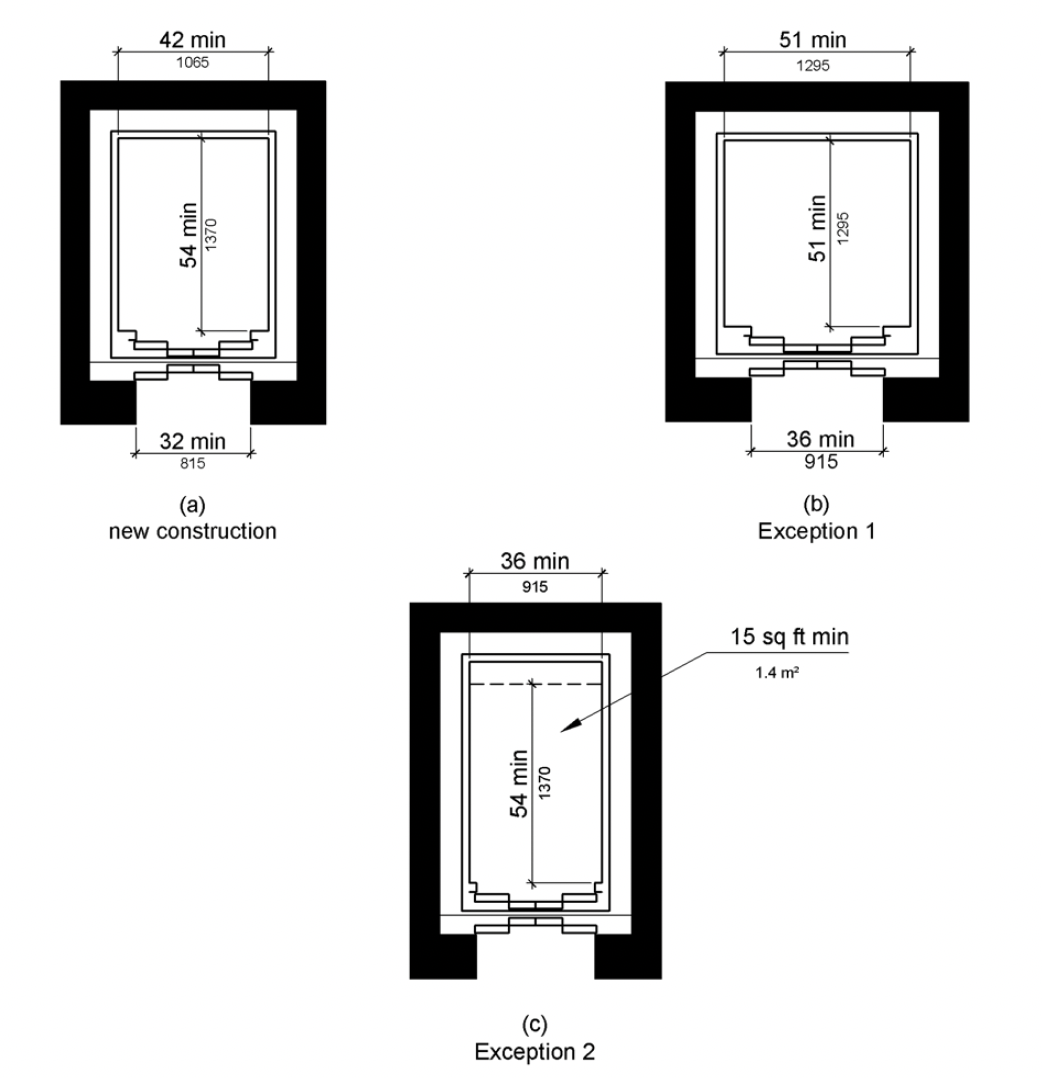

Section 407.4 of the ADA Standards for Accessible Design addresses requirements for elevator cars, ensuring they meet accessibility standards to serve individuals with disabilities effectively.

- 407.4.1 Car Dimensions: Elevator cars must have a minimum inside dimension of 42 inches in width and 54 inches in depth, with doors providing a minimum clear opening width of 32 inches. These dimensions facilitate accessibility for wheelchairs and other mobility aids.

- 407.4.2 Floor Surfaces: The floor surfaces within elevator cars must comply with standards ensuring they are stable, firm, and slip-resistant to safely accommodate mobility aids and reduce slip hazards .

- 407.4.3 Platform to Hoistway Clearance: The clearance between the car platform and the hoistway must not exceed 1¼ inches, minimizing the gap for safety and accessibility .

- 407.4.4 Leveling: Elevator cars must be equipped with self-leveling features that maintain the car level with the landing within a tolerance of ½ inch under all loading conditions, enhancing the safety during entry and exit .

- 407.4.5 Illumination: The illumination levels in the elevator car, particularly at the controls, platform, threshold, and landing sills, must be a minimum of 5 foot-candles to ensure visibility for all users, including those with visual impairments .

- 407.4.6 Car Controls: Controls in the elevator must be easily accessible and usable, complying with reachability and operability standards suitable for individuals with disabilities .

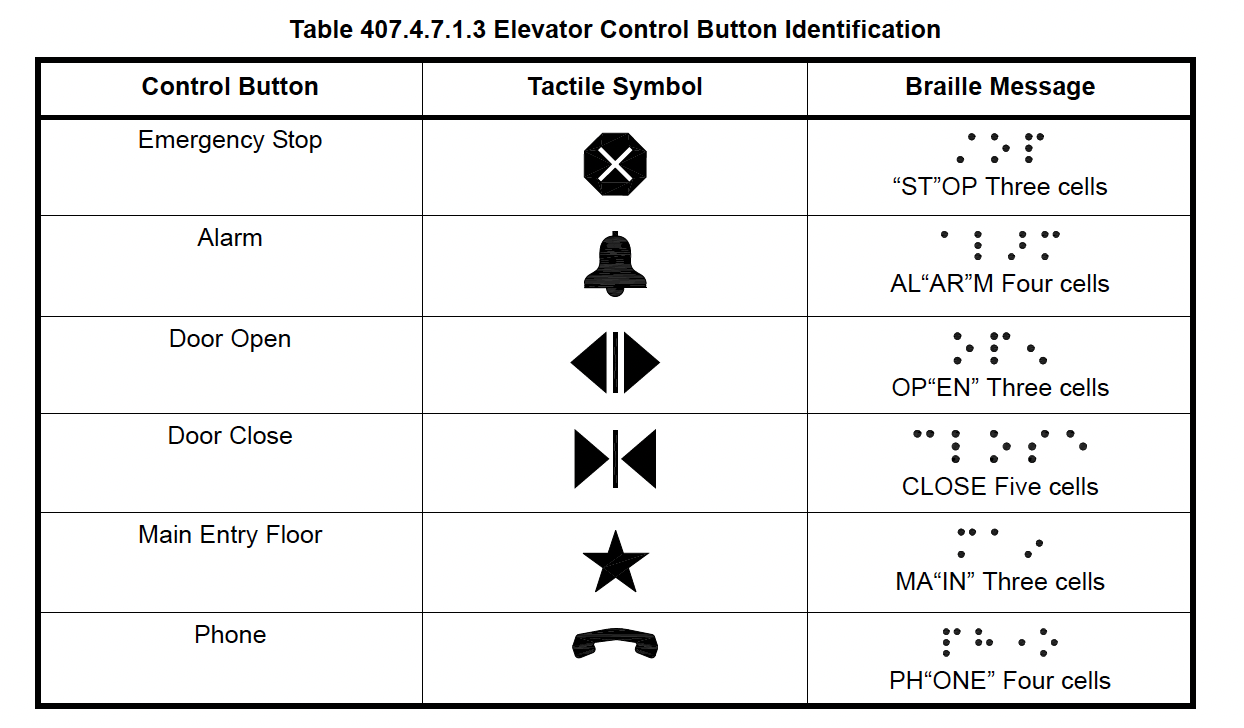

- 407.4.7.1.3 Elevator Control Button Identification: Specifies the requirements for the tactile symbols used on elevator control buttons for essential functions. This includes symbols for the emergency stop, alarm, door open, door close, main entry floor, and phone. These control buttons must be identified with specific tactile symbols, as outlined in a detailed table, to ensure they are easily recognizable and usable by persons with visual impairments. This design consideration enhances the accessibility and safety of elevator systems.

This section ensures that elevator cars are designed and equipped to accommodate the needs of individuals with various disabilities, promoting independence and safety in public and private buildings.

Elevator Cars

Section 408.4 specifically addresses LULA elevators, which are Limited Use/Limited Application elevators designed for low-traffic, low-rise applications where a full-sized passenger elevator would not be feasible. LULA elevators are a practical solution for providing accessibility in small public buildings, churches, and private businesses. They are subject to many of the same ADA standards as full-sized elevators but with some modifications that reflect their intended use in smaller settings:

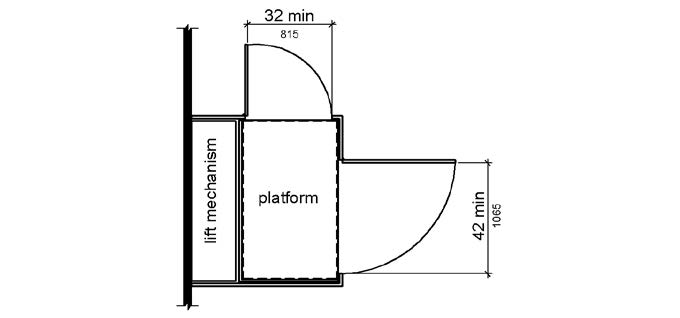

- 408.4.1 Car Dimensions and Doors: LULA elevator cars must provide a clear width of 42 inches minimum and a clear depth of 54 inches minimum. Car doors must be positioned at the narrow ends of cars and shall provide a minimum clear width of 32 inches. Exceptions allow for variations in dimensions under specific conditions, such as existing elevator retrofitting.

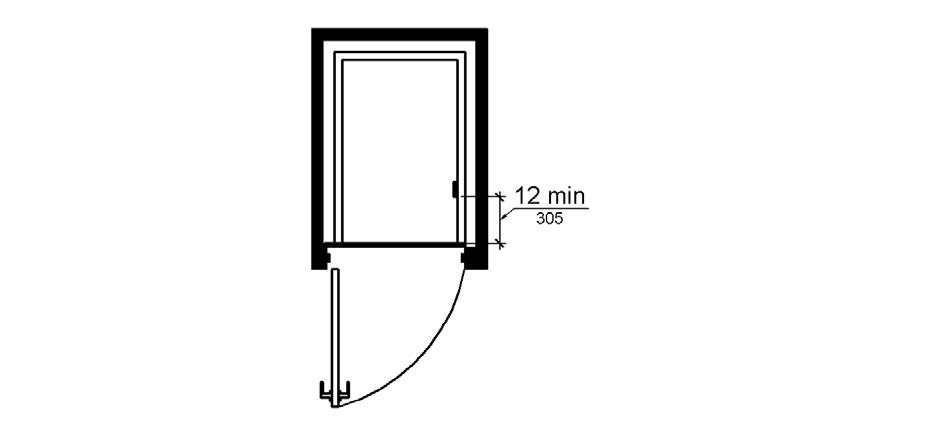

Section 409.4 pertains to private residence elevators, detailing the requirements these elevators must meet within residential dwellings:

- 409.4.6.2 Location of Controls: Controls must be installed on a side wall, 12 inches minimum from any adjacent wall, ensuring they are easily accessible and do not require excessive reach, which could be difficult for some users.

These sections highlight the ADA’s commitment to accessibility by tailoring requirements to the specific contexts of LULA and private residence elevators, ensuring they meet the needs of users in these environments.

Platform Lifts

- General Compliance (410.1): Platform lifts must adhere to ASME A18.1 standards (either 1999 or 2003 editions), ensuring they are not attendant-operated and allow for unassisted entry and exit.

- Floor Surfaces (410.2): The floor surfaces of platform lifts must comply with specific provisions to ensure safety and accessibility.

- Clear Floor Space (410.3): Adequate clear floor space must be maintained in the lift to accommodate users, including those in wheelchairs.

- Platform to Runway Clearance (410.4): A maximum clearance is specified between the platform sill and any runway landing to ensure safety during lift operation.

- Operable Parts (410.5): All controls must be accessible and usable, following the guidelines for operable parts to ensure they can be used by persons with disabilities.

- Doors and Gates (410.6): Doors or gates on platform lifts must be low-energy and power-operated, complying with specific standards to ensure accessibility. There’s an exception for platform lifts serving only two landings, which can have manual doors or gates.

These regulations ensure that platform lifts are safely accessible to all users, particularly those with disabilities, enhancing mobility in various environments.

Conclusion